Additive Manufacturing

We're working with customers to make cleaner, more economical goods. We don't only create CFRP products; we employ CFRP processing to make certain metals more lightweight and rigid.

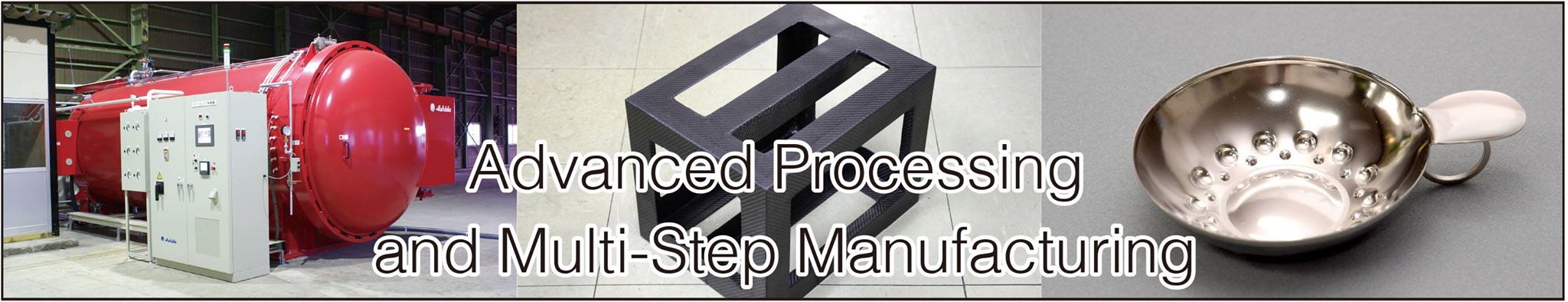

Multi-Process Manufacturing

With over 50 years of experience, we have the skills to get the most out of all types of metals. To achieve the optimum and most economical product for you, we can perform any number of assembly processes.

Hajime Saito

Secondary Processing7th-year employee

Secondary processing is mainly about deburring, tapping, counter sinking, creating extruded holes and the like. Our job isn't glamorous or flashy, but we're the unsung heroes of metalworking. Imagine a palanquin--you've got your noble sitting on top, and the palanquin bearers underneath holding them up. But have you ever thought about who makes the bearers' shoes? That's us. Without us, the whole production would be hobbled. Fujiseiki's strength is in recognizing the importance of everyone and being able to do everything in-house, from sheet metal to assembly. We know our customers' satisfaction is tied to our accuracy and quick order completion times, and we're always striving to make the customer happy.