Toshihiko Nakazawa

Blanking2nd-year employee

Blanking is the foundation of Fujiseiki. When our customers demand absolute accuracy, we deliver absolutely. We will follow their blueprint to a T. When a project leaves my hands, I don't think, "Ah, good, that's over with;" I am always thinking about how to make it easier for the next person to handle. You have to strike a balance between speed and precision, and you can't become too fixated on one detail. It's a good policy to exchange ideas and techniques with others, too. Everyone at Fujiseiki has good communication with each other, and we share information and stay aware of everyone's activities. We stay tightly networked, which makes everyone's jobs easier and creates an enjoyable work atmosphere.

Sometimes you need things like covers, caps, and curves for your project. Sheet metal and bending aren't always associated with this kind of challenge, but Fujiseiki brings to the table a variety of techniques that can come at this problem from more than one angle. We are adept at creating circular edges and lips as well as pieces that have unusual rounded angles--all without the use of a die, meaning faster and cheaper production for you. You no longer need to go through the hassle of customizing a die that needs to be tweaked again and again. We can replicate the results of a die or stamping/press processing with consistent quality and accuracy, perfect for prototyping and limited series. Of course, if you want to take it to mass production, we can quickly create dies based on these bending pieces.

Since you don't need a die, you'll get your project produced and delivered that much faster.

Hiroki Shimoda

Bending5th-year employee

When you're bending, you have to be aware of the raw material and your measurements. You have to keep the next assembly process in mind as well. You can't simply rely on machines for everything; you need a human element. A machine will follow the numbers you input, but your hands and eyes will tell you if you're in line with the overall project.

The communication between departments is good here. No matter what you do, there's going to be times of bottlenecking, and processing will become backed up. But with good teamwork like ours, you can reduce this and mitigate the burden you place on others.

The communication between departments is good here. No matter what you do, there's going to be times of bottlenecking, and processing will become backed up. But with good teamwork like ours, you can reduce this and mitigate the burden you place on others.

Amada HDS 8025 NT

Trumpf TrumaBend V85S

Welding in particular requires a high degree of skill. We train all of our staff on site so that our techniques are passed down directly from one welder to the next, ensuring consistent and reliable quality.

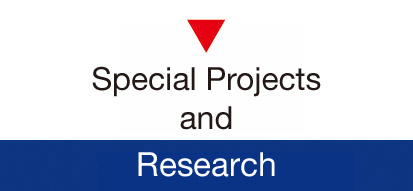

YAG welding

MAG・TIG welding

We utilize all types of welding so we can use the optimal technique for your project. From small, intricate pieces to large factory equipment frames, Fujiseiki has a flexible range of capabilities. We work with steel, stainless steel, aluminum, titanium, brass, and more.

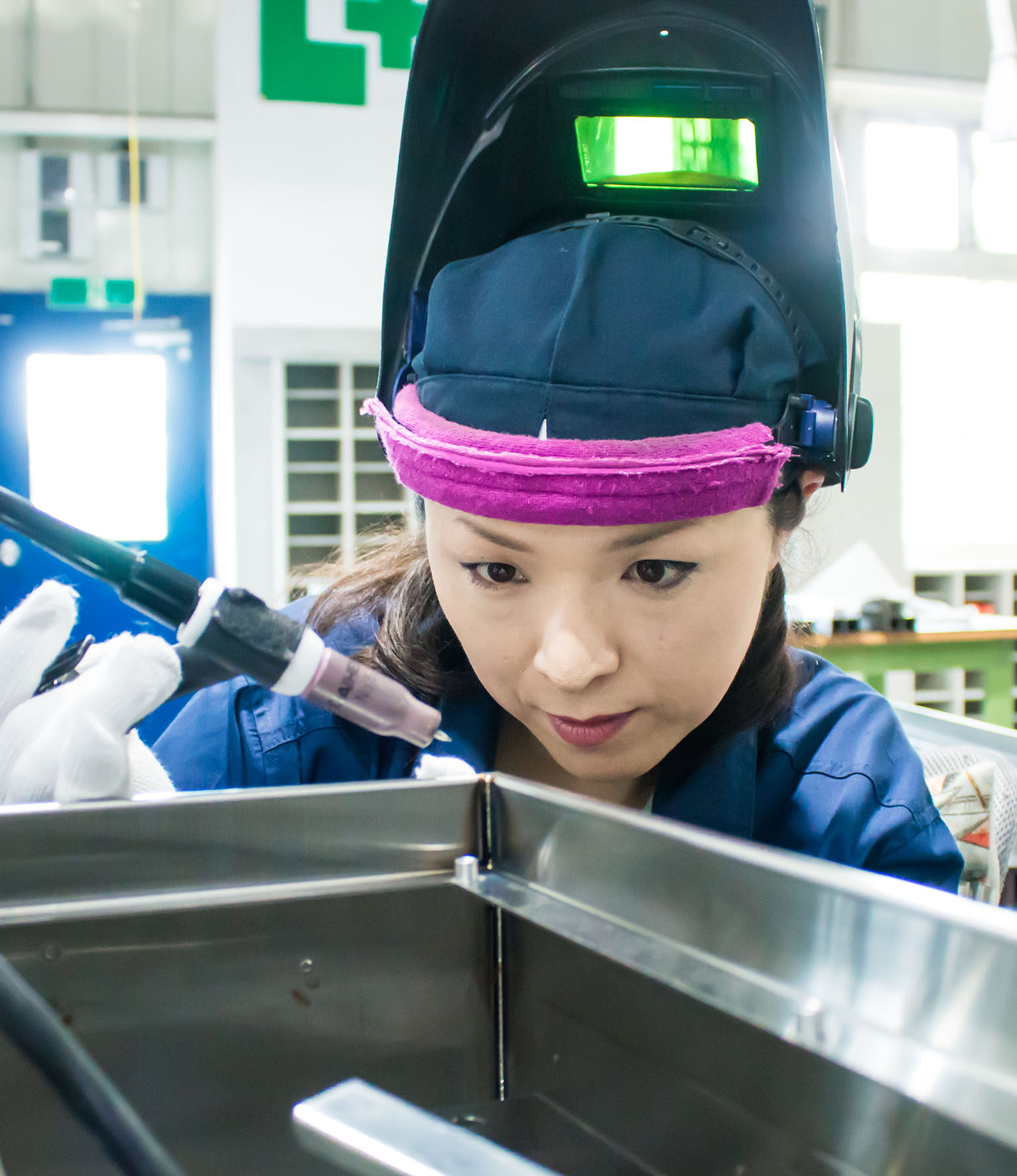

Shiho Sato

Welding6th-year employee

In welding, you have to get to know the material you're working with so you can use the right welding technique. For stainless steel, you use TIG ultraviolet or infrared fiber laser YAG. For metal like steel you can use processes like semi-automatic welding.

When you're welding, though, you have to be able to concentrate without getting distracted. You achieve a kind of zen while working, and while in this state, you have to remain meticulous.

In 2017, I attended an event held by the prime minister where workers got to exchange ideas and opinions with each other. I met the prime minister and was even invited to his residence to talk about my experiences at Fujiseiki. We discussed the process for obtaining my welding license, what I've accomplished, and my current projects and activities. It was a rare opportunity and a great experience.

When you're welding, though, you have to be able to concentrate without getting distracted. You achieve a kind of zen while working, and while in this state, you have to remain meticulous.

In 2017, I attended an event held by the prime minister where workers got to exchange ideas and opinions with each other. I met the prime minister and was even invited to his residence to talk about my experiences at Fujiseiki. We discussed the process for obtaining my welding license, what I've accomplished, and my current projects and activities. It was a rare opportunity and a great experience.